A CNC machinist/programmer’s role is highly skilled, so finding (and keeping) a good one can be difficult – even more so if you don’t know much about CNC machining. Along with welding skills, CNC skills are in short supply, which can make it even harder to find a good machinist.

The good news? We’re here to help you find the right CNC machinist for your organization. In this article, we’ll look at:

What CNC machining involves

CNC machinist job roles and description

CNC machinist’s salary range

How the CNC machinist test works

How to use our pre-employment skills assessment to find CNC-skilled candidates

Which tests to include in an assessment for CNC

Finding a great CNC machinist may seem like a daunting task, but we’re here to show you how skills-based testing can empower you to make more informed hiring decisions, as well as making the whole process faster, fairer, and much less stressful.

Table of contents

- What is CNC machining?

- CNC machinist job description and responsibilities

- Essential skills for a CNC machinist

- CNC machinist salary expectations

- What is the CNC Machinist test?

- Use a pre-employment skills assessment to help hire the best CNC machinist

- What tests should you include in a CNC machinist assessment?

- Start your skills-based hiring process and say goodbye to CVs

What is CNC machining?

Here, we’re just going to have a brief and simple overview of what CNC machining is.

CNC stands for Computer Numerical Control, and it is a manufacturing process where pre-programmed computer software controls the movement of factory tools and machinery.

The process can be used to operate a range of machinery, including grinders and lathes, mills, and CNC routers. Three-dimensional cutting tasks can be accomplished with a single set of prompts and is a much faster and more efficient process than the old manual methods of machining.

The production of parts is mostly automated these days by pre-programmed software. The dimensions for a specific part are set into place with computer-aided design (CAD) software. This is then converted into a finished product with computer-aided manufacturing (CAM) software.

CNC machining is a vital part of the metal and plastic industries, and has been adopted across all areas of the manufacturing sector, including:

Aerospace

Transportation

Defense

Firearms

Commercial

Electronics

Medical

Optical

Oil and gas

Marine industry

CNC machinist job roles

The title “CNC machinist” covers a broad range of jobs. In reality, there are a variety of different roles in a CNC environment. These positions are reliant on one another and all are crucial to the industry.

The three basic CNC job roles are:

Operator: This entry-level role is often taken by those just getting started in the industry. Basically, an operator’s job is to load stock material and run parts. They operate the machine but don’t have any input in programming it.

Set-up operator: This person is responsible for loading the program, and selecting and setting up tools. They must also test the program, and ensure everything works correctly. Those working in this position also step in and fix errors when things go wrong.

CNC machinist/programmer: This role involves taking a blueprint and figuring out how to make the part. This includes picking out tools and determining the speeds and feeds. They also write the programs controlling the machines in CNC programming languages called G-code and M-code.

In this article, we’re going to focus on the role of the CNC machinist/programmer.

CNC machinist job description and responsibilities

A CNC machinist/programmer is highly skilled. They perform detailed machine setups, programming using the G and M codes, machine process improvement, and troubleshooting. They also produce machined parts using a range of CNC machines.

Job responsibilities include:

Prepare, operate and/or supervise the operation of CNC machines that are used to cut, drill or calculate

Perform machine setups quickly, accurately, and efficiently

Select equipment and materials, read operational directions and codes, and interpret specifications to prepare program sheets

Set material dimensions and location on the machine table

Examine raw material for dimensions, quantity, defects, and required heat lot/certification numbers

Inspect finished work to verify dimensions and meet specifications

Ensure that safe work practices are followed and adhered to

Document manufactured quantities using the ERP system

Monitor and document operational/performance issues and provide feedback to the supervisor

Develop and maintain good working relationships with colleagues, supervisors, and others

Work with the Engineering department to improve machining processes

That’s a lot of job responsibilities, so CNC machinists also need a range of skills in order to be successful in the role.

The best insights on HR and recruitment, delivered to your inbox.

Biweekly updates. No spam. Unsubscribe any time.

Essential skills for a CNC machinist

It’s usual for machinists to have some form of CNC qualification from a college or technical school, as well as two or three years of experience on the job.

CNC and coding skills are just the tip of the iceberg, though. A great machinist needs other technical, physical, and soft skills to do this job. We’re going to look at the most relevant skills for the role in this section, and why they are important.

Later, we’ll show you how to create a full pre-employment skills assessment for a CNC machinist using a variety of skills tests that include language, math, AutoCAD, and management skills, along with our CNC machinist (imperial measurements) test.

Language skills

A CNC machinist needs to be able to read and understand safety rules, operating and maintenance instructions, and any procedural information. They also have to write reports and communicate effectively with others, so they must have good language skills.

Mathematical skills

The ability to work with mathematical concepts like portability and statistical inference is crucial to CNC machinist roles. In addition, an understanding of the fundamentals of plane and solid geometry and trigonometry is essential to candidates’ success. Machinists must also be capable of applying concepts such as fractions, percentages, ratios, and proportions to practical situations.

Reasoning ability/problem solving

Machinists are faced with problems and errors many times, so it’s essential they can solve practical problems and deal with a variety of situations that require reasoning ability.

Instructions are given to machinists in written, verbal, diagram, or schedule methods. This means that they must have a clear understanding of what these instructions are and how to carry them out.

Management skills

A CNC machinist/programmer has often worked their way up from the CNC operator’s position, and a machinist is often responsible for supervising operators and set up operators.

Good management skills are crucial if a CNC machinist is to be overseeing other employees. Bad management or lack of these skills can cause other staff members to leave and have an impact on productivity.

Physical skills

Perhaps because the technical skills of CNC machining are so important, physical ability is often overlooked. However, machinists need to be physically fit to do the job, because it can involve carrying loads of up to 50lb occasionally, as well as being in a standing position most of the day. Machinists are also sometimes required to stoop, kneel, crawl or crouch.

Because CNC machining is such a visually demanding and detail-oriented job, candidates should also have excellent close vision, distance vision, and peripheral vision, and be able to adjust the point of focus in their vision.

Many employers are willing to make reasonable adjustments for employees with disabilities where they can, but it’s not always practical in this role.

CNC machinist salary expectations

How much does a good machinist cost? Salaries vary according to different factors, including location and experience. The 2022 salary range for a CNC machinist/programmer in America is between $48,797‒$62,393, and the average salary is around $55,068.

What is the CNC Machinist test?

At TestGorilla, we have worked with CNC experts to create a thorough test of candidates’ CNC skills. Our CNC Machinist (imperial measurement) test evaluates the applicant’s competence in this field, where knowledge and know-how can only be gained with experience and time spent machining.

This test will show candidates’ skills in operating a CNC machine correctly. It also ensures that they possess the problem-solving and machining skills needed to manufacture parts.

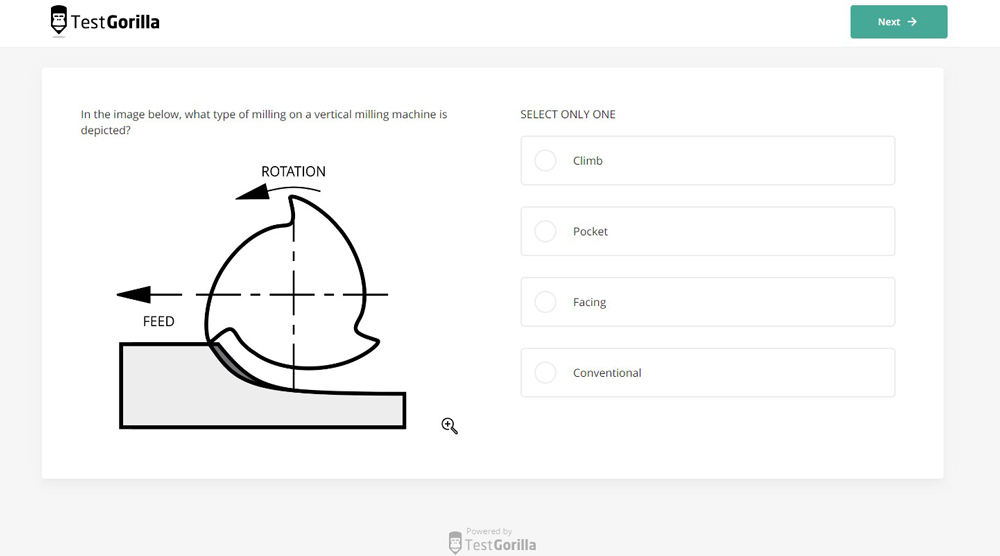

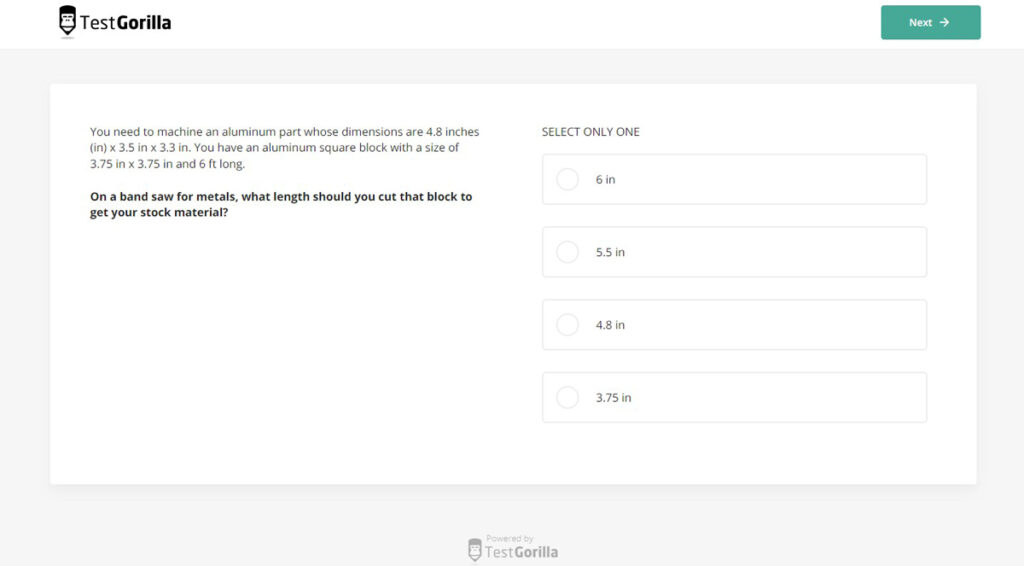

Below are a couple of example questions from the test, so you can see first-hand the types of questions that candidates are asked:

Use a pre-employment skills assessment to help hire the best CNC machinist

As we mentioned earlier, in this section we’re going to focus on how you can bypass the old-fashioned and time-consuming method of going through piles of CVs to find promising candidates.

We understand how frustrating it is to discover the ideal applicant on paper, only to find out that they stretched the truth about their CNC machining skills in the interview. It’s back to square one for you, along with the wasted time and money spent on recruitment.

It’s no secret that we at TestGorilla are passionate about relegating the CV to history with skills-based hiring. When you look at it logically, it all makes sense. Remove the often-inaccurate resume from the hiring equation, (wouldn’t that feel good? No more lost hours of your life spent trawling through thousands of CVs) and replace it with data-driven skills-based hiring.

This scientifically-backed method enables you to quickly find candidates who have proven through a skills assessment that they have the hard and soft skills to do the job well.

Our assessments consist of up to five skills tests which are taken back-to-back by the candidates in one sitting. We recommend that you use the assessment at the start of the hiring process for maximum efficiency. You can choose which tests to include from the huge range in our constantly-growing test library, and you can even include customized questions.

Once you have set up an assessment, you simply send the link to candidates and they take the assessment. You then receive the results and make the decision on which applicants to take on to the interview stage based on their scores. Our tests are created and updated by subject-matter experts, so you can be sure that the top-scoring candidates have the skills they need.

Skills-based hiring is the simple, streamlined, and stress-free alternative to the CV.

What tests should you include in a CNC machinist assessment?

As mentioned earlier, there are a variety of tests that will combine well with our CNC machinist test. It does depend on the specific role that you are hiring for, but good choices include:

Language tests

It’s essential that CNC machinists aren’t just fluent in CNC coding languages, but also in the native language of your organization. This is crucial because they need to be able to follow both written and verbal instructions closely, and may have to give instructions to other workers too.

We have a range of language tests based on the CEFR framework, ranging from elementary (A2) through to proficient (C1). By including a language test in your assessment, you’ll know before the interview which candidates have the required fluency level in your chosen language.

Math test

Math skills are crucial for CNC machining, and we have an intermediate math test that will evaluate candidates’ skills in solving math equations and problems involving fractions, decimals, percentages, ratios, and time calculations.

Leadership and management test

Because CNC programmers often have management of CNC operators working with them, it’s essential that they have good leadership and managerial skills. This is not just because they will manage team members effectively, but also because good managers reduce staff turnover and encourage motivation.

Our Leadership and management test evaluates candidates’ skills in delegating authority and task responsibility, as well as planning and supporting the development of others. Applicants who score well in this test have also demonstrated that they can provide timely guidance and feedback, and gain acceptance of ideas and plans.

AutoCAD test

The AutoCAD test is one of the newest additions to our test library. CNC machining requires candidates to have a thorough understanding of Computer Aided Design (CAD) in order to set design specifications for whatever is being manufactured.

The AutoCAD test evaluates candidates’ ability to produce, edit, and manage drawings relevant to any industry in both 2D and 3D. This screening test will help you hire design experts who are skilled in AutoCAD and require no extra training.

Take a look at our test library for more ideas

Of course, these are just suggestions, and you may find more relevant tests for your specific CNC open role in our test library.

These could be a mix of technical and soft skills, or perhaps one of our personality tests such as the Big 5 (OCEAN) test to gain deeper insight into your candidates’ personality traits and how well they align to the job role.

Start your skills-based hiring process and say goodbye to CVs

We hope this article has been helpful to you in your quest to hire a CNC machinist. It can be hard to decide where to start, especially if you aren’t experienced in CNC machining yourself.

We’ve looked at what CNC machining involves, a CNC machinist’s job roles and description, as well as a CNC machinist’s salary range, and how to use the CNC test as part of a pre-employment assessment to simplify and speed up your hiring process.

If you’re ready to ditch the CV pile and join us in forging the future of skills-based hiring, and want to know more about how to get the process started, our comprehensive guide to creating an assessment answers your questions and will get you up and running in no time.

Sign up for your TestGorilla free plan (it takes less than a minute) to get started on building your first assessment. If you want more information or to see how our products work first-hand, book a free 30-minute live demo with our sales team, who will be pleased to answer any questions you may have.

You've scrolled this far

Why not try TestGorilla for free, and see what happens when you put skills first.